From Vision to Reality: CAD, CAM, and Precision Design in Metal Fabrication

In the world of metal fabrication, the journey from a concept to a tangible reality is a fascinating blend of innovation and precision.

At the heart of this transformation lies Al Shurooq Industries L.L.C.'s commitment to harnessing the power of advanced design

technologies—CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). These technologies bridge the gap between

vision and execution, ensuring that every component created meets the highest standards of quality and accuracy.

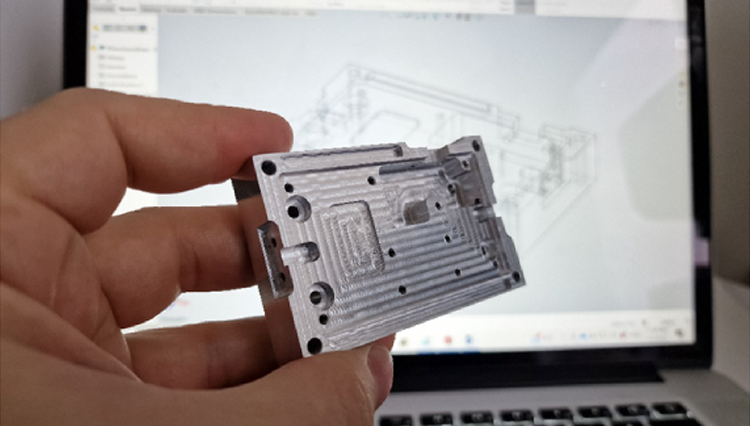

CAD: The Blueprint of Innovation:

Computer-Aided Design (CAD) is the bedrock upon which Al Shurooq Industries L.L.C. builds its intricate components.

CAD software empowers designers and engineers to create detailed virtual models of products. This technology not only

allows for precise measurements and calculations but also offers the flexibility to iterate and optimize designs

before production even begins.

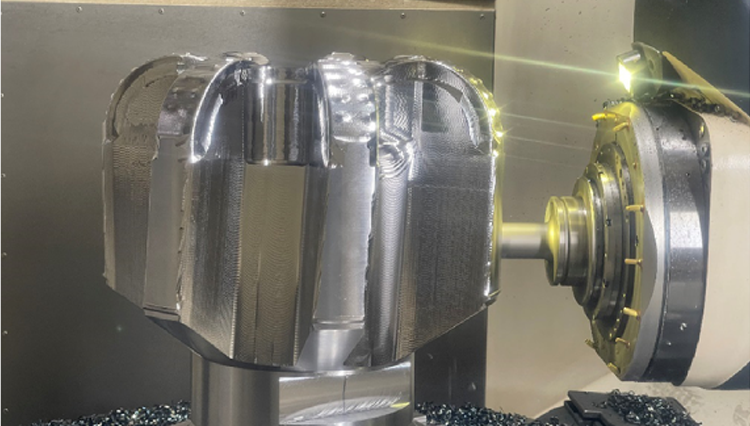

CAM: Translating Vision into Action:

The synergy between CAD and CAM is where innovation takes shape. Computer-Aided Manufacturing (CAM) uses the data from CAD to automate

the manufacturing process. This integration ensures that the design's intricacies are replicated with utmost accuracy during production,

minimizing human error and maximizing efficiency.

Precision at Every Step:

The journey from vision to reality is a meticulous process at Al Shurooq Industries L.L.C. It begins with the creation of a CAD model,

where designers meticulously define dimensions, shapes, and tolerances. Once the model is finalized, CAM takes over, generating

toolpaths and instructions for CNC machines to follow. This seamless transition from virtual design to physical production

guarantees that the end product mirrors the original concept.

Efficiency and Accuracy:

CAD and CAM are more than just tools; they're the backbone of efficiency and accuracy in modern metal fabrication.

The use of these technologies streamlines the entire process, from conceptualization to production, reducing lead

times and ensuring that components are manufactured with precision.

Simulations: Paving the Way for Perfection:

One of the most remarkable aspects of CAD and CAM is the ability to simulate real-world scenarios.

Engineers can subject virtual prototypes to stress tests, simulations, and even simulate the manufacturing process itself.

This preemptive testing helps identify potential issues and allows for optimizations before any physical production occurs.

A Paradigm Shift in Metal Fabrication:

Al Shurooq Industries L.L.C.'s reliance on CAD and CAM represents a paradigm shift in metal fabrication. The integration of these technologies

isn't just about efficiency—it's about elevating quality and precision to unprecedented levels. Every component that leaves the company's

facility bears the mark of innovation, design excellence, and meticulous attention to detail.

Crafting the Future:

The journey from vision to reality is where Al Shurooq Industries L.L.C.'s commitment to innovation and precision truly shines.

The marriage of CAD and CAM empowers the company to craft components that don't just meet standards but surpass them.

As industries evolve, the company remains poised to redefine what's possible, one meticulously designed and executed

component at a time.

In the world of metal fabrication, Al Shurooq Industries L.L.C. isn't just transforming metal—it's shaping the future through the seamless

fusion of vision, technology, and precision.